Thermal conductivity is a fundamental concept in physics, engineering, and material science. It describes a material’s ability to conduct heat and is essential in designing buildings, electronic devices, industrial machinery, and everyday objects. Understanding the thermal conductivity unit of measure is crucial for engineers, students, researchers, and anyone working with heat transfer. In this article, we provide a detailed guide to thermal conductivity, its measurement units, factors affecting it, practical applications, and methods for accurate evaluation.

What Is Thermal Conductivity?

Thermal conductivity describes a material’s ability to conduct heat. It quantifies the rate at which heat energy passes through a material due to a temperature difference. In simple terms, it tells us how well a substance can transfer heat from a hotter region to a cooler one.

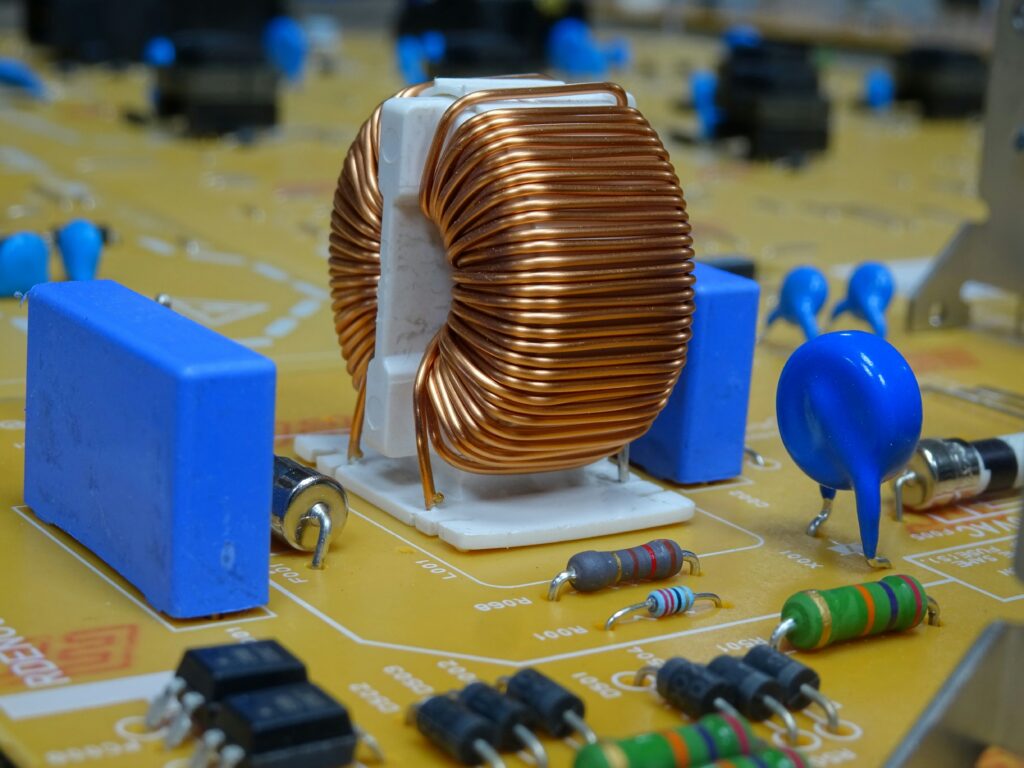

Materials with high thermal conductivity, like copper and aluminum, conduct heat rapidly. Materials with low thermal conductivity, like wood, plastic, or glass wool, act as thermal insulators, slowing down the flow of heat. Understanding this property is vital in designing energy-efficient buildings, electronic devices, heat exchangers, and industrial processes.

Unit of Measure for Thermal Conductivity

The unit of measure for thermal conductivity depends on the measurement system being used. In the International System of Units (SI), the standard unit is:

- Watt per meter per Kelvin (W/m·K)

Explanation of SI Unit

- Watt (W): Unit of power, representing the rate of energy transfer.

- Meter (m): Unit of length, indicating the distance through which heat is conducted.

- Kelvin (K): Unit of temperature, representing the difference in temperature across the material.

Thus, 1 W/m·K indicates that 1 watt of heat flows through a 1-meter thickness of material when a temperature difference of 1 kelvin exists across it.

Other Units of Thermal Conductivity

Although SI units are the most widely used, other systems employ different units:

- Calories per centimeter per second per degree Celsius (cal/cm·s·°C) – used historically in older engineering texts.

- British Thermal Units (BTU) per hour per foot per degree Fahrenheit (BTU/hr·ft·°F) – used in the United States and some engineering applications.

For practical use, engineers often convert these units into SI units for consistency.

Factors Affecting Thermal Conductivity

Thermal conductivity is not a fixed property; it depends on several factors that influence how heat travels through a material.

1. Material Type

- Metals (e.g., copper, aluminum, silver) have high thermal conductivity due to free electrons facilitating heat transfer.

- Non-metals (e.g., wood, glass, rubber) have low thermal conductivity because they rely on slower molecular vibrations to transfer heat.

2. Temperature

Thermal conductivity can vary with temperature. For metals, it generally decreases as temperature rises, while for some non-metals, it may increase with temperature.

3. Density and Structure

- Dense materials generally have higher thermal conductivity because closely packed molecules transfer heat efficiently.

- Porous materials like foam or aerogels have lower conductivity because air pockets reduce heat transfer.

4. Phase of Material

The state of matter—solid, liquid, or gas—affects thermal conductivity. Solids usually have higher thermal conductivity than liquids or gases due to stronger intermolecular interactions.

Measuring Thermal Conductivity

Accurate measurement of thermal conductivity is essential for scientific research, engineering design, and industrial processes.

Laboratory Methods

- Steady-State Methods: Measure thermal conductivity when temperature remains constant. Examples:

- Guarded Hot Plate Method: Material placed between a heated plate and a cold plate. Heat flow is measured.

- Heat Flow Meter: Monitors heat transfer through a sample using thermocouples.

- Transient Methods: Measure thermal conductivity under changing temperatures. Examples:

- Laser Flash Method: A laser pulse heats one side of a sample, and the temperature rise on the other side is recorded.

- Transient Plane Source (TPS): Heat is applied using a sensor, and thermal response is measured.

Instruments and Tools

- Thermocouples and infrared cameras for temperature measurement

- Calorimeters for heat energy detection

- Heat flux sensors to measure heat flow

Each method has advantages depending on material type, sample size, and required accuracy.

Applications of Thermal Conductivity

Thermal conductivity is crucial in multiple fields. Understanding its units and values allows engineers and scientists to design systems that either conduct or insulate heat effectively.

1. Building and Insulation Materials

Materials with low thermal conductivity are used as insulators to reduce energy loss in buildings. Examples: fiberglass, polystyrene foam, and aerogels. High conductivity materials are used for heat dissipation, such as in heating elements.

2. Electronics and Heat Management

Modern electronics generate significant heat. Thermal conductivity values are critical for designing heat sinks, cooling systems, and thermal interface materials to prevent overheating and improve efficiency.

3. Industrial Applications

In industries such as metallurgy, chemical processing, and energy, knowing the thermal conductivity of materials ensures proper heat exchangers, furnaces, and reactors operate efficiently and safely.

4. Everyday Applications

- Cookware (metal pots and pans with high thermal conductivity)

- Refrigeration and HVAC systems

- Automotive engines and components

Thermal Conductivity vs Thermal Resistance

Thermal conductivity is related to thermal resistance, but they are not the same.

- Thermal Conductivity (k): Measures how well a material conducts heat.

- Thermal Resistance (R): Measures how well a material resists heat flow.

The relationship is:

R=Lk⋅AR = \frac{L}{k \cdot A}R=k⋅AL

Where:

- LLL = thickness of the material

- AAA = cross-sectional area

- kkk = thermal conductivity

Designers use this relationship to calculate insulation effectiveness and heat transfer rates.

Common Mistakes in Measuring Thermal Conductivity

Accurate measurement requires careful attention. Common mistakes include:

- Using incorrect units and failing to convert them properly

- Ignoring temperature effects, especially for materials with temperature-dependent conductivity

- Improper sample preparation, leading to air gaps or uneven surfaces

- Failing to account for anisotropic materials, which have directional conductivity variations

Real-Life Examples of Thermal Conductivity Units

To better understand thermal conductivity, let’s look at common materials and their units of measure (W/m·K):

| Material | Thermal Conductivity (W/m·K) |

| Silver | 429 |

| Copper | 401 |

| Aluminum | 237 |

| Steel | 50 |

| Glass | 1.1 |

| Wood (oak) | 0.17 |

| Polystyrene foam | 0.03 |

These examples show the wide range of thermal conductivities across different materials, from metals to insulators.

Conversion Between Units

Sometimes, thermal conductivity is expressed in non-SI units. Conversion formulas include:

- 1 W/m·K = 0.5778 BTU/hr·ft·°F

- 1 W/m·K = 0.239 cal/cm·s·°C

Correct unit conversion ensures consistent calculations in international projects and research.

Importance of Understanding Thermal Conductivity Units

Knowing the unit of measure for thermal conductivity is critical for:

- Accurate scientific calculations

- Designing efficient energy systems

- Safety in industrial processes

- Material selection for construction, electronics, and manufacturing

Without a clear understanding of units, calculations could be inaccurate, leading to design failures, safety hazards, and increased costs.

Frequently Asked Questions (FAQs)

1. What is the SI unit of thermal conductivity?

- The SI unit is Watt per meter-Kelvin (W/m·K).

2. Why is thermal conductivity important?

- It determines how heat moves through materials, essential for insulation, electronics, and industrial applications.

3. Can thermal conductivity change with temperature?

- Yes, it varies depending on material type and temperature range.

4. Are there non-SI units for thermal conductivity?

- Yes, older systems use cal/cm·s·°C or BTU/hr·ft·°F.

5. How is thermal conductivity measured?

- Using steady-state methods (guarded hot plate) or transient methods (laser flash, TPS).

Future Applications of Thermal Conductivity

With modern technological advances, thermal conductivity remains critical:

- Development of high-performance insulation for energy-efficient buildings

- Heat management in electronics, including CPUs, batteries, and LED devices

- Nanomaterials and composites, which rely on precise thermal conductivity for functionality

- Advanced manufacturing and 3D printing, requiring exact heat transfer control

Conclusion

The thermal conductivity unit of measure is a key concept for understanding heat transfer in materials. Expressed in W/m·K, it provides a standard way to quantify a material’s ability to conduct heat. Thermal conductivity is influenced by material type, temperature, density, and structure, and it is crucial in fields ranging from construction to electronics to industrial engineering.

By understanding thermal conductivity units, engineers, scientists, and students can make accurate calculations, select appropriate materials, and design efficient systems. Mastering this concept ensures safety, performance, and energy efficiency in real-world applications.

Whether you are working with metals, polymers, ceramics, or insulation, thermal conductivity units provide the foundation for all heat transfer calculations and applications.